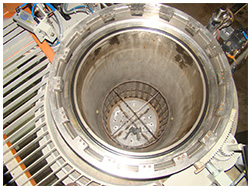

the ceramic core leaching autoclave

Our Machines

After Knockout, ceramic shell fragments and cores still remain. It is very difficult or impossible to remove this shell material by mechanical means. The simpler method is to chemically dissolve these shell segments. The CDS -50P allows for removal of such ceramic fragments from the cast components in the shortest possible time, with no risk of damage to the cast component itself.

The Process

Parts are placed in baskets and lowered into a pressure vessel which is filled with an aqueous caustic solution. The pressure and temperature is raised and the process begins. The cycle time depends on the ceramic composition, component geometry, leachant concentration, temperature and the pressure it is subjected to.

Essential Process requirements :

This being a critical process, it must be conducted under controlled conditions and followed with post leaching operations.

- The concentration & formulation of the feed aqueous caustic solution must be suitable to dissolve the ceramic at set processing temperature, pressure and time.

- A good part of the shell ceramic must be removed by knockout and blasting. Only such ceramic that is not accessible may be leached.

- The shell chemistry must be such that it can be leached by hot pressurised aqueous caustic solution.

- After pressurized leaching, the components must be flushed with dilute mineral acid to neutralise all the remaining traces of Alkali from the component surfaces.

- Retention of alkali on the component can enhance hot corrosion cracking if the component is intended for high temperature operation.

The leaching cycle :

Load castings basket – Fill caustic –Close & lock quick-lock door – set required temperature & cycle time – initiate heating – controlled burping and repressuring auto starts – hold at set temperature & pressure for preset time – drain & vent at end-of cycle – open autoclave door – remove castings – drain discharge tank to ETP after the caustic has cooled.

Standard Equipment Features :

The Leaching autoclave includes the Caustic mix tank with vent, rinse water reservoir, dump tank with steam vent, control valves, inlet & exhaust pipes, caustic fill & rinse pump, safety devices & interlocks, gauges and actuators. The quick-lock door of our proven proprietary design is manually actuated by a rack & pinion arrangement

- Plug and Play Design.

- Safe Operation.

- Long door gasket life.

- Complete functional safety, proven design.

- Performance track record.

- World class engineering.

- Design Code: ASME VIII.

- Inspection by Notified body.

- Batch operation.

- PLC control.

- Touch screen operation.

- Size : Available in 2 standard sizes. (Depths indicated excludes dished ends)

- ID600 X 1000 Depth

- ID750 X 1100 Depth

- ID900 X 1200 Depth

- Custom sizes available on request.

World Class Backup Service :

- All our machines come with comprehensive LNTech support services.

- We feel we offer the Best Back-Up Service in the industry.

- Spares for the service life of all of our machines are easily available worldwide.

- All our machines come with a Comprehensive Instruction and Installation Manual.

- The service section of the user’s manual gives complete details of all bought out parts , with suppliers name, and suppliers part number, this saves our customers substantial sums of money.