The investment casting operation consist of multiple stages, each of which affects the quality, price, and lead time of the cast parts. While the attention is frequently put on the wax injection, shell building, and metal pouring stages, shell knockout is just as important. The safe and efficient removal of the ceramic shell from the casting pays dividends in downstream productivity, finishing costs, and yield. A modern foundry’s indispensable tool is the Pneumatic Shell Knockout Machine.

Investment Casting and Shell Knockout

After the construction, drying, and firing of the ceramic shell, molten metal is introduced into the shell cavity. Once the metal cools to a manageable temperature and solidifies, the ceramic shell must be taken off to reveal the metal casting. This process is referred to as shell knockout or shell removal.

Back then, workers used hammers or chisels to knock shells loose by hand. Even though that worked fine now and again, it took lots of effort, made constant noise, delivered uneven results, while often harming parts or hurting people. When factories started making more pieces and shapes grew trickier, machines slowly replaced old ways – pneumatic rigs stepped in because they handled jobs faster, kept things steadier, plus lowered danger around the shop.

Understanding Pneumatic Shell Knockout Machines

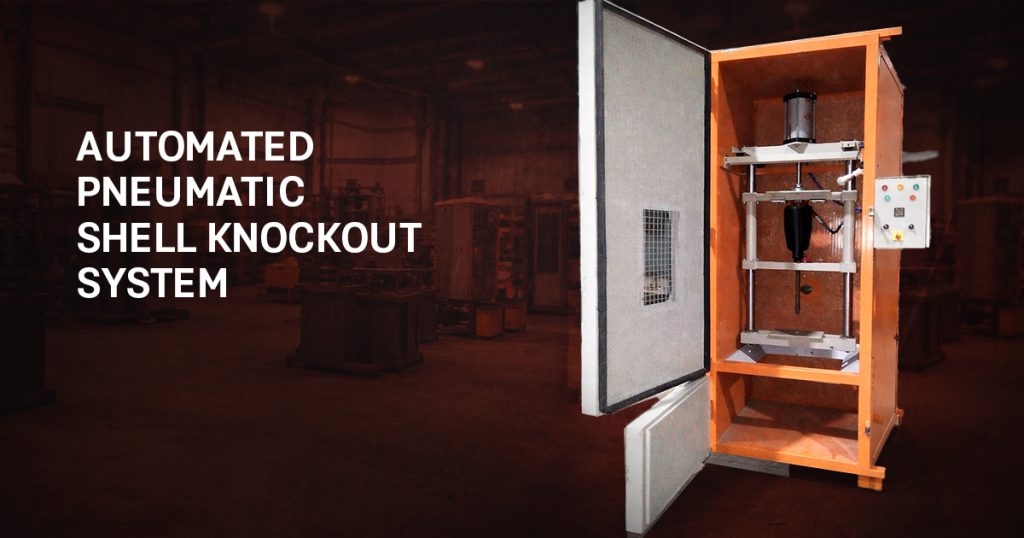

Sometimes, breaking ceramic shells off cast trees needs precision. That job often falls to a tool made just for it – the Pneumatic Shell Knockout Machine. Instead of brute force, it uses bursts of air pressure to deliver measured strikes. These impacts loosen the shell without harming the casting underneath. Usually housed in a frame, the unit includes an air-powered hammer mechanism. A fixture holds the tree steady during operation. Vibration dampeners may be part of it, helping reduce wear. Some models feature adjustable intensity settings. Others come with quick-release clamps for faster loading. While simple in concept, its role in post-casting cleanup proves essential. Operation tends to stay consistent across different setups. Over time, reliability makes up for limited flexibility. Foundries rely on it mainly because alternatives take longer. With routine maintenance, downtime stays low. Efficiency here doesn’t mean speed alone – it means repeatability too.

• A heavy duty pneumatic hammer

• Adjustable carriage or fixture for holding cast trees

• An anvil or impact surface

• Acoustic enclosure for noise reduction

• Optional dust collection system

Air under pressure drives the tool that breaks apart the hard outer layer through steady blows. What remains untouched is the solid metal part inside. Evenness in clearing away fragments comes naturally from how it is built. Little need arises for someone to step in and adjust things manually.

Out in tough foundries, Laxminarayan Technologies

built their pneumatic shell knockout setups to last. These units keep working smoothly, day after day. Fewer breakdowns mean less downtime. Performance stays steady under pressure. Tough materials handle constant use. Maintenance needs stay small over time. Design focuses on reliability above all else.

Key Components and Design Features

Pneumatic Hammer System

Inside every machine beats a pneumatic hammer. Not like those fussy mechanical setups full of gears and levers – this one works straight, strong, steady. Its power hits just right, tuned by hand depending on how thick the shell, what size the cast, which alloy’s used. What matters most? It never quits when needed.

Adjustable Carriage with Amphitheater Style Anvil

A single twist sets the cradle to fit trunks big or small. When struck, the fan-shaped base cups the trunk firmly, spreading shock smoothly through every jolt.

Acoustic Enclosure

Noise comes with shell knockout by nature. Yet inside Laxminarayan Technologies setup, air-powered systems get wrapped in sound-dampening covers. These barriers cut down loudness sharply. Workers then face less noise exposure. Comfort rises alongside safety when decibels drop.

Dust and Debris Control

A shattered ceramic casing produces tiny particles and scraps. With a dust extractor attached, the knock-out unit keeps workshop surfaces tidier, supports better breathing conditions for staff, while also aiding daily cleanup routines.

Pneumatic Shell Knockout Machines Offer Speed And Consistent Force

1. Increased Productivity

Starting by hand takes time, results often uneven. Machines powered by air deliver steady strikes, one after another without pause. Because of this, a shop can move through batches faster, hour after hour. Output climbs when each step follows the last like clockwork.

2. Stronger casting safety and quality

A fragile casting can break when the shell comes off. Using air-powered tools with care helps prevent dents, splits, or harm to the finish. Less waste shows up in the numbers once impacts are managed well.

3. Reduced Labor Dependency

Facing fewer workers while demands climb, firms turn to machines. When air-powered knockouts ease heavy work, people stay sharper longer. Less handwork means teams shift toward jobs that need thinking more than strength.

4. Noise and Environmental Control

A loud machine tucked inside a soundproof box means less noise hitting workers’ ears, which keeps things within legal safety limits. Pair that setup with a vacuum pulling away fine dust, and it handles floating bits of tile too.

5. Low Maintenance Long Service Life

Years of steady work come naturally to these shell knockout units. Built tough, they keep going without constant care. Simplicity drives their design – air-powered strength that lasts. Fewer breakdowns mean less time waiting, more time running. Durability isn’t an add-on, it’s built in from the start.

Models Offered by Laxminarayan TechnologiesTo fulfill a wide range of production needs Laxminarayan Technologies provides a variety of pneumatic shell knock out machines.

LITE Model : Suitable for small foundries, prototype shops, or low volume production.

STD (Standard) Model: For medium scale foundries which require a balanced performance and efficiency.

HEAVY Model: Built for high volume, heavy duty applications which have large or thick shell castings.

We have engineered each model to put forward reliable performance which in the same time takes into different casting sizes and production rates.

Understanding the pneumatic shell knockout process

Once cooled, the cast tree gets positioned on a movable carriage that can be adjusted as needed.

With the tree held steady, alignment happens between tool and surface. Next, contact forms where hammer meets support structure. A precise setup ensures everything lines up before force is applied. That stability matters when connecting equipment to wood.

Fragments begin to fly when the air-powered tool strikes. Its steady beats crack open the hard coating piece by piece. Pressure builds with each hit until the outer layer splits apart.

Beyond the crack, pieces drop off into a bin below. Where there’s a dust setup, air pulls through to catch fine particles drifting loose.

Once cleaned, castings go through inspection before heading into later finishing steps.

With less hands-on work, the system keeps shell extraction steady. Efficiency comes through smooth operation every time around.

Integration With Modern Foundry Automation

Finding their place in modern foundries, pneumatic shell knockout machines support the shift to smarter production. While factories adopt connected technologies, these units link up smoothly with automatic mold assembly lines. Alongside robots that carry castings, they keep pace without extra adjustments. Even when data tracking runs the floor, integration happens naturally behind the scenes.

Knockout data helps fine-tune how fast things run, set up service timing, while also boosting how well processes are managed. So instead of being just an ending task, shell knockout becomes something precise you can track and adjust.

Economic and Operational Benefits

At first glance, buying a pneumatic shell knockout machine means spending more upfront. Still, savings grow over time because fewer workers are needed. Mistakes drop sharply, which cuts down wasted material. Speed picks up too, moving parts through quicker than before. Workers face less risk, making conditions safer overall. Money saved adds up, balancing out the early cost.

Fine adjustments begin where foundries team up with Laxminarayan Technologies, shaping setups that match real demands. This path keeps spending under control while holding tight to solid cast results. Choices get made on the spot, driven by what each shop actually faces.

Shell Knockout Technology Future Outlook

As needs grow sharper, so will the tools that shape them. Expect smarter machines taking charge step by step. Dust won’t vanish, but handling it gets a serious upgrade. Think tighter links between physical work and digital oversight spreading through foundries. Progress isn’t sudden – it builds quietly where precision meets care.

Built on straightforward mechanics, air-powered systems still hold their ground when shaping molten materials. Their consistent performance shows up across many foundry tasks without fuss. Where conditions shift rapidly, they adjust without complex upgrades. Simplicity keeps them running where others struggle.

The Pneumatic Shell Knockout Machine is a crucial part of modern investment casting operations. With the pneumatic impact shell removal system, foundries can improve productivity, safety, and casting consistency. Laxminarayan Technologies pneumatic shell knockout solutions are tailored to the current and future needs of foundries. For manufacturers, a pneumatic shell knockout machine is a reliable, low-maintenance, and high-performing shell removal equipment. It is an investment toward operational excellence.