The investment casting sector continues to progress toward advanced automation, precision, and control of processes. With increasing global competition, coupled with the need for better surface finishes, stringent quality assurance, and consistent requirements, the industry is moving away from conventional manual methods of shell building. Robotic shell building is no longer confined to the realms of theory—it is rapidly becoming viable and scalable for foundries that wish to enhance operational efficiency, repeatability, and cost management.

Evolution of Shell Building Technology

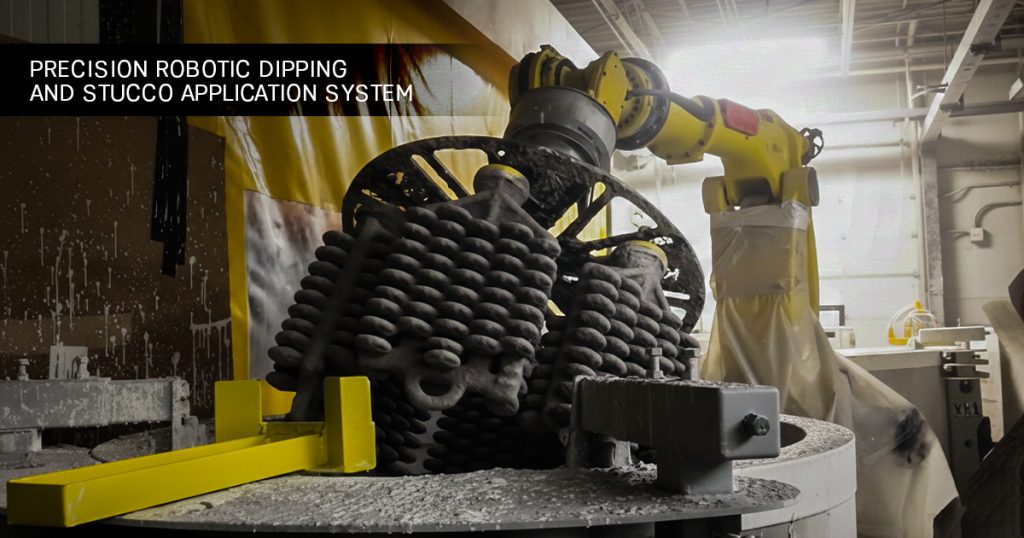

Shell formation has been the key stage in investment casting for years. What we see in the quality of the shell is that it plays a great role in dimension accuracy, surface finish, and the overall cast integrity. In the past shell building was very much a manual process which included dipping, stuccoing and drying. Although a skilled operator may do a good job, manual processes are by nature variable and hard to scale. Robotic shell building is a big step forward in technology. By what they do which includes automation of the dipping, draining, stucco application and material handling robots remove human variation and bring in consistency and repeatability in shell quality. As the industry grows we see less focus only on production volume and more on process stability and quality assurance which is what robotics does best.

Importance of Quality Control in Robotic Shell Building

As shell building becomes more automated, quality control must become more sophisticated. Robotic shell building allows foundries to tightly control every parameter involved in shell formation. This is particularly important as casting designs become more complex and tolerance requirements more demanding.

Key process parameters controlled in robotic shell building include:

• Dipping speed and immersion time

• Drain time and drain angle

• Slurry temperature and viscosity

• Stucco grain size and application consistency

• Drying time and environmental conditions

• Robot path accuracy and repeatability

Any variation in these parameters can affect shell thickness, permeability, and strength. Robotic systems ensure that once parameters are set and validated, they are maintained consistently across every pattern and every batch.

In contrast to manual shell building, where adjustments depend on operator experience, robotic shell building relies on data-driven control. This enables faster troubleshooting, reduced scrap rates, and improved traceability.

Slurry and Material Consistency

The enterprising nature of robotic shell building pairs with strict quality control of slurry and materials. Robots will carry out programming to the letter, meaning any deviation in quality of slurry will immediately reflect in the quality of the shell. This compels foundries to implement more robust slurry testing and monitoring.

Key properties of slurry include:

• Viscosity and flow behavior

• Temperature stability

• Gel strength and bonding characteristics

• Solid content

Consistent slurry properties allow robotic systems to offer and maintain coating thickness and minimize faults, such as runs, thin spots, or inclusions. Integrated with robotic shell building, automated slurry management systems further improve the reliability of the process.

Productivity and Process Efficiency

With no doubt one of the strongest motivators for implementing robotic shell building is productivity. Robotic systems can run with very little downtime, and offer predictable cycle times, and increased throughput. Than manual operations, robotic processes do not suffer from fatigue, variation in technique, or inconsistent timing.

This includes the following benefits:

- Less dependent on labour

- Faster shell build cycles

- Improved line balancing

- Decreased rework and rejection rates

- Better utilization of floor space

These benefits are precious for foundries with high volume production for the complex components in aerospace, automotive and industrial. This is indicative of lower cost per casting and improved delivery reliability.

Flexibility for Different Casting Requirements

A common issue is that of robot use in shell construction which we see in terms of a large variety of pattern sizes and geometry. Today’s robotic solutions are put forth with flexibility as a key feature. What we see is that robots which are programmed for motion, which also have variable tooling options and which are built with modularity into the design are what foundries are using. At Laxminarayan Technologies we see that robots which are put together to do shell building can be tailored to handle:.

- Small precision components

- Medium and large industrial castings

- Complex geometries with undercut

- High shell layer counts

This variability which in turn does not limit production capacity but rather improves it.

Sustainability Through Efficient Material Use

More folks care about the planet these days when making cast parts. Machines that build shells help because they use less stuff and leave behind fewer scraps.

Key sustainability benefits include:

1.When slurry gets spread carefully, too much is avoided.

2.Every patch spreads just right, so none of it goes to waste

3.Reduced rejects lower overall resource consumption

4.Higher-grade shells mean less need to melt things down again.

Fresh floors, tidy spaces – machines handle daily cleanup without a hitch. Safer paths emerge when clutter fades into order behind their steady motion. Rules around air and waste grow easier to follow once dust and debris get managed nonstop. Workers move with more confidence where robots keep things clear. Fewer spills, less mess overall changes how smoothly each shift runs.

Smart Foundry Integration

A single robot shaping shells slips right into today’s smarter foundry setup. With digital brains, eyes that sense changes, plus records kept at every turn, machines track what happens as it unfolds – each run sharper than the last.

Potential integrations include:

- Slurry property sensors and feedback loops

- Environmental monitoring for drying rooms

- Production data analytics

- Predictive maintenance for equipment

Finding their way into Industry 4.0, foundries now rely on robotic shell building to power smart, linked production lines – this shift quietly reshapes how things are made.

Economics of Robotic Shell Building

Few question whether machines cost more up front compared to hand-built methods. Still, savings pile up fast through fewer workers needed, less wasted material, better output quality, along with steadier manufacturing flow – balancing out the early price tag before too much time passes.

Finding enough workers gets tough, yet machines keep operations running smooth. When costs climb, staying steady matters – robots help hold things together without missing a beat.

Finding the right setup often means teaming up with makers of machinery – take,Laxminarayan Technologies for example. When foundries do that, choices around automation fit how much they produce, what kinds of castings they handle, plus financial limits. Their path changes based on these factors.

Future Outlook

The future of investment casting will play out in terms of precision, repeatable results, and sustainability. Robotic shell construction is the key tech which will bring about this change. As systems progress to greater complexity we may see also see greater degrees of automation, integration, and process intelligence. Instead of supplanting expert knowledge what robots do is they put it into practice with great consistency. Foundries which adopt this tech will position themselves for success in very tough markets.

Conclusion

Robotic implementation in shell building is a natural outgrowth of investment casting tech. Through the use of automation which in turn brings in tight quality control, material optimization and digital integration we see how this improves upon what today’s foundries are presenting. For companies that want better productivity, better shell quality, and sustainable practices,Laxminarayan Technologies robotic shell building systems present a proven and looking toward the future solution. As industry expectations go up, putting in robotic shell building isn’t just a choice — it is a strategy requirement.